A basic overview of what I've done over the years

2021

Project: Output-Based Adaptive Mesh Refinement in STAR-CCM+

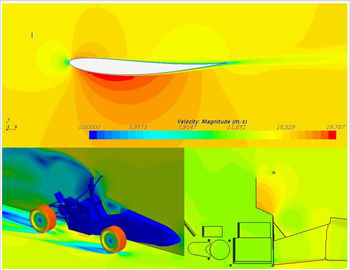

Output-based Adaptive Mesh Refinement (AMR) is the use of the adjoint solution to determine the contribution of cells within the domain to an engineering output of interest, and automatically refining the cells with the highest error. Fundamentally, this is what we all want from our meshes, the most accurate (lift/drag/etc) number with the smallest cell count.

This type of AMR is the topic of my MASc thesis, so I figured it'd be neat to try and implement it for some practical applications in STAR-CCM+.

In the article I wrote on LinkedIn, I ended up applying it to a multi-element rear wing for an FSAE car, and an inviscid simulation of a "wingless missile". I also list all the steps required to implement it for yourself.

https://www.linkedin.com/pulse/implementing-output-based-amr-star-ccm-david-penner

Project: Simulating the Williams FW43B(AR), Part 1: All Simulations Are Wrong

At the start of 2021 F1 season, Williams mistakenly released a model of that year's car, the FW43B, to the public via a mobile app of theirs. While this model had some issues, it's the most accurate model of an F1 car that the public as ever had access to, and with a bit of work, can be used for CFD.

Reaching "proper" F1 CFD results will take time, so I've split the project up into three articles: CFD methodology, geometry reconstruction, and final results. This is the first of those articles, where I do a deep dive into the CFD methodology used for the car, getting feedback from ex-F1 aerodynamicists along the way.

To quote one of those aerodynamicists: "This is by far the best and most realistic CFD of an F1 car I have seen available to the public", "Without comparisons to wind tunnel deltas I can’t be certain that this model is useful but, in some areas like mesh quality, it looks even better than the CFD we had at my former team."

2020

BSc Thesis: Mesh Adaption for Detached Eddy Simulation using Precursor RANS Simulations

When I was doing the DES for the previous year's poster presentation, I was faced with computational restrictions and had to make the mesh as efficient as possible. I had read papers about using the turbulent length scales to evaluate the mesh resolution, and decided to go the opposite way; using the predicted length scales from RANS to make an adapted mesh.

A quick rundown on the method I developed:

-

Run a RANS simulation

-

Create a refinement function calculated as the maximum of set multiples of the Integral, Taylor, and Kolmogorov scales of turbulence

-

Use a shielding function to restrict the refinement zones to areas of resolved turbulence in the scale resolving simulation. I prefer using the total pressure coefficient to do this.

-

Create a new mesh, using the refinement function for adaption

The end results were positive, resulting in a 40% mesh reduction from a traditional mesh to an adapted mesh (210M -> 110M cells) with the same results, however that could be a testament to how inefficient my 'traditional' mesh was. Properly testing this methodology will take a lot more work than a BSc thesis.

In the end, I was awarded the Professor C.P. Bennett Thesis Award, for the best thesis (of 7 students) in the Mechanical Engineering thesis elective

Internship: Aerodynamics at Tesla

At Tesla, I was working as an intern within the (Thermal Systems) Aerodynamicists team, taking care of all HVAC related aerodynamics.

My projects included:

-

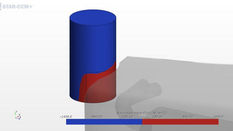

Evaluating the use of Volume of Fluid (VoF) CFD with Adaptive Mesh Refinement (AMR) for the simulation of water ingress into vehicle fresh air intakes

-

Designing the side window defrost ventilation system for the 2021 Model S/X refresh using Tesla’s Airwave 2 technology, working with supplier, mechanical design, and studio teams

-

Provided aerodynamic feedback on surfaces for the Tesla Semi front grille and cooling fan module

-

Designed multiple high performance footwell ducts and vane patterns, minimizing flow dead-spots and pressure drop within packaging constraints

2019

Project: Formula SAE Drag Reduction System

In summer 2019 I went to the national CFD conference in London, Ontario, CFD2019, held by the CFD Society of Canada. I didn’t have any sort of university funding or faculty support, so going was purely for fun as I wanted to participate in the Undergraduate Student Poster Competition.

I had prepared a poster on the “Optimization and Analysis of a Formula SAE Drag Reduction System”, where I found an optimum open position of the rear wing flaps, the passive losses created by the system, and the re-attachment behaviour airflow after closing using detached eddy simulation.

This work got me 1st place in the competition, after which I turned it into a conference paper for the 2020 SAE Word Congress Experience.

Be sure to set the video to 720p - 50fps, and to focus on the wake of the rear wing at 1.65 [s]!

Learning outcomes:

-

Adaptive meshing for DES

-

Overset meshing

Formula SAE: PBR20

PBR19 wasn't built because of issues with getting a mold for our monocoque, so it was rebranded again, this time as PBR20.

The aero kit was mostly the same, with just the side aero removed, an additional front wing element for more aerobalance adjustability, and simplified rear wing mounting.

Virtual competition for this season was a personal success, with my design judge saying I'm at the 'design finals' level. My design presentation can be found here.

Skills developed:

-

Keeping it simple

Capstone Project: Concrete Extruder CFD

For the senior year mechanical engineering project (capstone) at the University of Manitoba, all projects are industry sponsored from local companies, and are allocated based on student preferences. I opted for the “Optimization of a Non-Circular Void Concrete Extruder”, involving the CFD optimization of a hollow-core concrete extruder, which creates pre-cast concrete slabs for construction. The problem was that the concrete wasn't filling in the full shape of the die, leaving some unintentional voids in the slab.

This was interesting CFD, which involved the use of rotating reference frames, the Herschel-Bulkley non-Newtonian fluid model (a combination of a Bingham plastic and power law fluid), and for the final runs, transient analysis involving rotation of the auger meshes.

While the client was happy with our final results, I would have preferred to spend more time validating the viscosity model and CFD setup instead of being forced straight into design iterations.

One interesting thing I found was that each commercial package has their own implementation of the Herschel-Bulkley model, which allowed me to diagnose an issue the client had with some external CFD they contracted.

Learning outcomes:

-

Non-Newtonian modeling

-

Rotating meshes

2018

Formula SAE: Finish PBR17

As the team's build cycle was a bit off-kilter, and we had half a car from the year before that still needs to go to competition, we ended up finishing the build of PBR17 and re-naming it PBR18, also renaming the newly designed PBR18 as PBR19 in the process.

Going straight from no composites experience to having to build an aero kit from scratch wasn't easy, but I got by with a little help from my friends. I ended up laying up and processing about 15 CFRP components in the end.

Skills developed:

-

Composites manufacturing (and then some)

-

How to remove carbon splinters

-

How to quickly heal cuts from carbon

-

Identifying the smell of CFRP dust

Formula SAE: PBR18 Oil Sloshing (Volume of Fluid)

PBR18 was our first car to have a dry sump, and our Engine Lead wanted to see if his baffles in the oil tank would keep the oil down.

For the simulation setup, I had used lapsim data of PBR18, and found physical properties of 100C 10W40 oil online.

The lapsim data was almost too clean, as it was always driving on the edge of the friction ellipse, instead of the choppier driving we'd see from novice drivers in an FSAE car.

Skills developed:

-

Volume of Fluid (VoF) method

-

Using 'real-world' data for simulation conditions

Internship: Price Industries

After convincing my soon-to-be manager that he needed a CFD intern, I started my first internship as a CFD Analyst at Price Industries.

Here, we used ANSYS CFX to simulate air distribution of HVAC systems and evaluate the performance of different HVAC setups. We mostly used simplified models of our products in these simulations, and it was my job to improve our methodology for this.

The major projects included:

-

Making boundary conditions that could properly replicate the underfloor diffusers in the video+pictures to the right

-

Calibrating porous media models to match experimental data for perforated sheets used in our products

-

Simulating various products to create a catalogue of CFD results

Skills developed:

-

Working with production CAD

-

Calibrating and validating CFD to experimental results

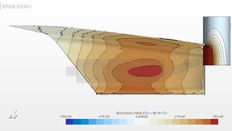

Formula SAE: PBR18 Oil Tank Radiation

If you look closely at the picture of PBR18 below, you'll see some gold tape on the oil tank, someone spent $100 on that tape because they were convinced it'd make a difference. I wasn't convinced, thankfully I had the tools to make my case!

It saved about 18 watts at best, relative to our 55,000 watt motor. Since the tape was also applied to areas that radiated more heat than they received, it actually insulated parts of the tank.

The most important part of this was the difficulties of radiation modeling. Emissivity is such a difficult quantity to get accurate numbers for online, so a lot of effort was put into finding the sensitivity of the simulation to this variable to ensure confident results were found.

Skills developed:

-

Radiation modelling

-

Appreciation for the difficulties of radiation modelling

Project: CFD Workstation V1

I needed some serious CFD resources and nothing available to me (FSAE lounge workstation, engineering compute nodes, my desktop) was really appropriate, so I invested in a purpose built CFD-only machine.

-$2000 later with some sketchy sever hardware from eBay in-hand, I had 20 cores and 128GB of RAM to do reasonably anything!

Specs:

-

2x Intel E5 2680 v2

-

128GB DDR3 RAM

-

128 GB SSD

-

2TB WD Red HDD

-

Nvidia Quadro 5000

Formula SAE: PBR19 Detached Eddy Simulation

I had a new big computer so of course I had to try some fancy CFD. I read some papers and learned how to properly set up DES. I was pretty out of my depth at the time and didn't get any really useful data, so this was mostly an exercise in trying new things

That being said, Chris Penny, Academic Account Manager for Siemens, saw it and was kind enough to feature it on the Siemens Formula Student and Formula SAE Forum.

https://community.sw.siemens.com/s/feed/0D54O000061xpffSAA

Skills developed:

-

Detached Eddy Simulation

-

Understanding of coherent structures

Formula SAE: PBR19

For the 2019 design season, I further iterated on the designs for PBR19 using what I had learned at FSAE Michigan 2018, Involving:

-

Redesigned airfoil profiles (from a catalogue)

-

Topology optimized front and rear wing mounts

-

Drag Reduction System (DRS)

-

Simplified manufacturing

-

Clamshell molds

Skills developed:

-

Aerodynamics

-

Topology optimization

-

Active aerodynamics

-

Design for manufacture

-

Aeromapping

-

Points sensitivity analysis

2017

Project: Computer Heat Sink (Conjugate Heat Transfer)

My first proper CFD project, I was in my 3rd year of undergrad and had been doing CFD for 3 months, my computer was disassembled at the time, I looked at my heat sink and said "hey, I can simulate that!". So I bought a pair of calipers, drew up the heatsink in SolidWorks using my laptop, put my computer together, and started simulating.

After that, I simplified the fins into a porous media approximation and calibrated the porous coefficients to match the resolved heatsink.

Skills developed:

-

Creating CAD from manufactured parts

-

Creating clean CAD for simulation

-

Conjugate heat transfer

-

Porous media modelling

-

Heatpipe modelling

Project: Desktop Computer (Conjugate Heat Transfer)

Summer 2017 - given the choice between a summer job building cabinets or staying at home and doing CFD, I opted for CFD. I spent the summer drawing up my computer, simulating each component one by one and eventually combining it into a unified model of my computer.

During a porous media conversion study,I realized that the best practices for porous media in electronics cooling weren't fully appropriate. As a result, I began splitting the porous resistances into the volumetric and entrance/exit losses for the media, as opposed to only using volumetric resistance.

Skills developed:

-

Fan modelling

-

Creating complex conjugate heat transfer simulations

-

Porous media modelling

-

Meshing

-

Conformal meshing

Formula SAE: PBR18

I start my 4th year and the Formula SAE team's Aerodynamics Lead disappeared. I was already the "CFD Guy" at this point, so I switched from electric to combustion and became the new Aerodynamics Lead.

Suddenly I had a section to manage, designs to make, the car from last year to build, and no idea what I was doing. The true FSAE experience!

In what was left of the design season I:

-

Redesigned the aero structures to save about 2 [kg]

-

Gained a bit of downforce with a swan neck and fancier front wing endplates

-

Started using laptime simulation to drive the design process

Skills developed:

-

Aerodynamics

-

Composites

-

Vehicle Dynamics

-

Laptime simulation

-

Finite Element Analysis

2016

Formula SAE Electric: Starting Aerodynamics

At the start of my 3rd year in undergrad I had been given an assignment on the Formula SAE Electric team to explore the aerodynamics of the car. Here I started off doing some CFD with the help of a grad student that was on the FSAE combustion team.